Production

System

Establish a comprehensive quality

control system for seed processing

and production

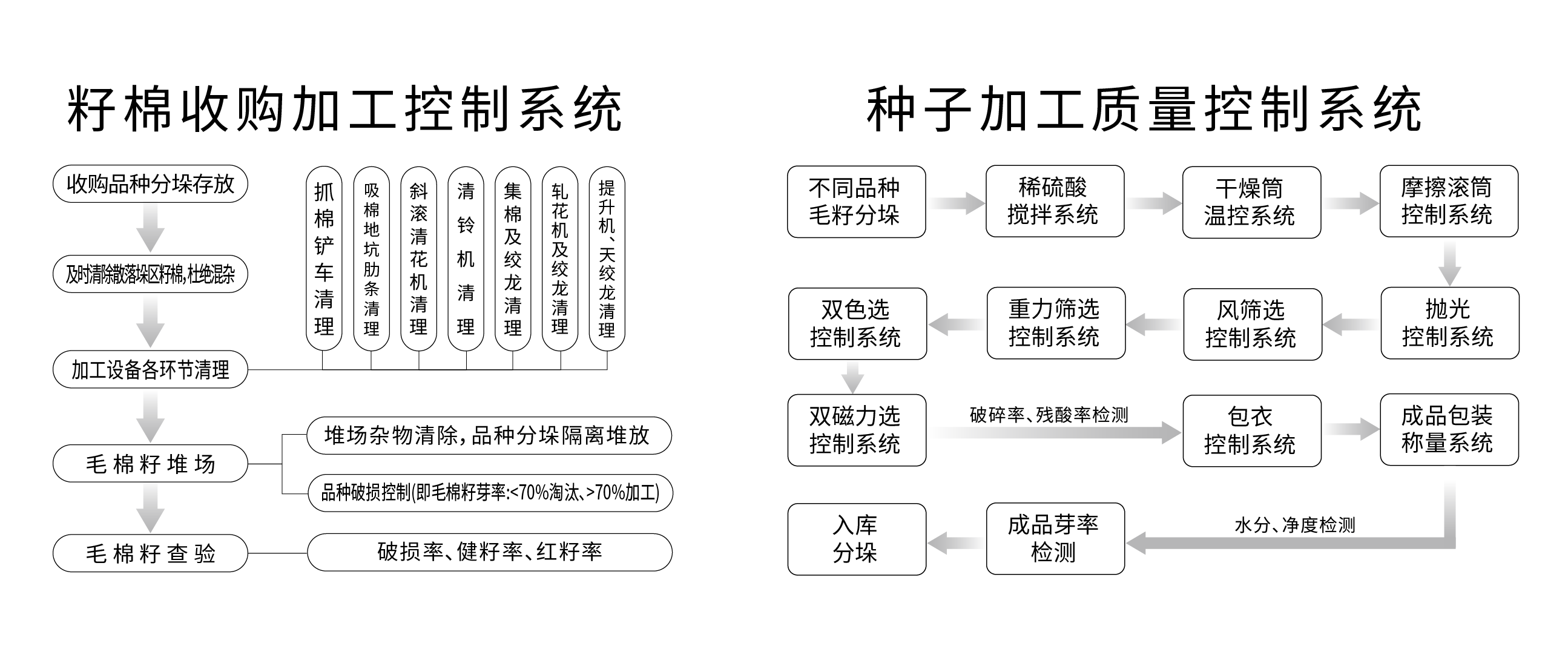

在现代种业种子加工生产过程中,健全完善的种子加工生产质量控制体系是确保种子质量的核心。新疆鸿泰种业经过多年的构建和完善已形成健全的种子加工生产质量控制体系和质量管理制度,2021年通过TS09001:2015国际质量体系认证。公司种子加工生产质量控制体系,主要分为籽棉收购加工控制系统和种子加工质量控制系统两大部分。

在籽棉收购加工控制系统中,从籽棉收购品种分垛存放开始,及时清除散落垛区籽棉,杜绝混杂,籽棉抓棉机、吸棉地坑肋条、轧花加工设备清理等步骤确保加工的规范。

种子加工质量控制系统中,对不同品种毛籽分垛堆放,防止品种混杂,入场毛棉籽及时检验,确保毛棉籽质量合格。采用稀硫酸脱绒、双色选、双磁力选加工工艺,跟班检验员定时检测种子破碎率和残酸率检测及时反馈检测结果,保障种子加工生产质量。采用国际知名品牌先正达生产的种衣剂对种子进行包衣处理,进一步提升种子质量。

成品种子入库前通过检验室发芽率、水分、净度检测合格后方可入库销售,确保种子进入市场最终质量。

种子加工生产质量控制体系,通过对各个环节的严格把控,确保了产品从原料到成品的质量,提升种子整体生产水平和产品市场竞争力。

In the processing and production of seeds in the modern seed industry, a sound and well-established quality control system for seed processing and production is the core to ensuring seed quality. After years of development and improvement, Xinjiang HillTide Seed Industry has formed a robust quality control system and a complete quality management system for seed processing and production, and obtained the ISO9001:2015 international quality system certification in 2021. The company’s quality control system for seed processing and production is mainly divided into two major parts: the seed cotton purchasing and processing control system and the seed processing quality control system.

Under the seed cotton purchasing and processing control system, starting from the separate stacking and storage of seed cotton of different varieties upon purchase, scattered seed cotton in the stacking area is promptly removed to eliminate cross-contamination. Standardized processing is guaranteed through a series of procedures, including the cleaning of seed cotton grabbers, ribs of cotton suction pits and ginning processing equipment.

With in the seed processing quality control system, fuzzy seeds of different varieties are stacked separately to prevent varietal mixing. Fuzzy cottonseeds are inspected immediately upon delivery to ensure they meet quality standards. The company adopts a processing technology featuring dilute sulfuric acid delinting, dual-color sorting and dual-magnetic separation. On-duty inspectors conduct regular tests on seed breakage rate and residual acid rate, and feed back the test results in a timely manner to ensure the quality of seed processing and production. In addition, seeds are coated with seed dressing produced by Syngenta, a world-renowned brand, to further improve seed quality.